弘埔技术(香港)有限公司

地址:上海市松江区米易路166号2幢301

传真:021-50701343

邮编:201615

新能源开发--纳米结构热电材料

2012-4-12 来源: 作者:|

|

Due to the ever increasing energy demand and growing global concern over the environmental impact of CO2 emissions, there is a need to seek solutions to transit from fossil fuels to sustainable energy.

It is known that of all the primary energy we harness and use, only 30% is translated into useful work. A staggering 70% is wasted as dissipated heat during energy conversion, transportation and storage. This huge loss is itself a source of recyclable energy. If the waste heat leakage can be minimized by having the heat harnessed, stored and reused, the additional available energy resources could be huge.1

Thermoelectric Materials

Thermoelectric (TE) materials hold great promise for converting waste heat energy into electricity. TE systems have many unique advantages, e.g. silent, reliable and scalable. However, the present use of TE devices is limited by their low efficiencies.2

To achieve the goal of high-efficiency energy conversion as well as cost effectiveness, the current traditional TE materials are not satisfactory. New generation TE materials have to be developed to bring about foreseeable impacts.

Energy Conversion Efficiency of Thermoelectric Materials

The energy conversion efficiency of a TE material can be evaluated by a dimensionless figure-of-merit

ZT = S2T/(rk),

where S, T, r and k are the Seebeck coefficient (also called thermopower), absolute temperature, electrical resistivity and thermal conductivity, respectively.3 Excellent TE materials should exhibit a large power factor (S2/r) for electrical properties as well as low thermal conductivity.

Although these parameters are inter-dependent in bulk materials, making it difficult to optimize the ZT values, several processing techniques have been applied to fabricate nano-materials or nano-composite materials, where the parameters in low-dimension can be varied independently as predicted theoretically.and demonstrated experimentally.4

In this article, several nanostructuring approaches for TE enhancement in different materials will be introduced.

Bismuth Telluride Thermoelectric Materials

Bismuth telluride (Bi2Te3) based TE materials are the most established materials for near room temperature applications, with ZT of ~ 1. Enhancements in ZT have been achieved in low dimension superlattice structure as well as in bulk nanostructured materials.3,5 The presence of nanostructures with sizes smaller than a phonon mean the free path can greatly enhance phonon scattering by scattering mid and long wavelength phonons, resulting in marked decrease in thermal conductivity. However, due to the high density of grain boundaries, electrons are also scattered efficiently, leading to a concurrent decrease in electrical conductivity.

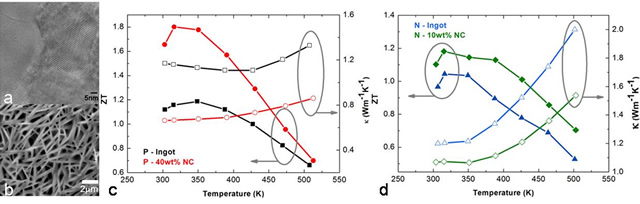

Hence, a practical solution will be the preparation of nanocomposites with controlled addition of a nanophase into the matrix phase. We have considered the approach of adding a nanophase with the same composition as the matrix phase. 6,7 In this process, the nanophase was prepared via a high throughput and economical melt spinning process. This process was implemented for both p-type Bi0.4Sb1.6Te3 and n-type Bi2Te3 systems. For n-type Bi2Te3, a maximum ZT of 1.18 at 42°C was obtained for the 10wt% nanocomposite while a maximum ZT of 1.80 was attained at 43°C for the p-type Bi0.4Sb1.6Te3 nanocomposite consisting 40wt% nanoinclusions. The significant improvement in ZT was attributed to the composites’ ability to retain a high power factor while at the same time drastically reducing thermal conductivity.

Figure 1. (a) Typical HRTEM and (b) SEM images of melt spun Bi2Te3 based composite materials and their enhanced ZT with decreased thermal conductivity of (c) p- and (d) n-type.

Compared with the decrease of thermal conductivity, which seems to be the primary benefit of nanostructuring for TE materials in most recent developments, the approach of power factor enhancement is more likely but has yet been rarely reported.8 We have demonstrated that by decreasing the grain size to de Broglie wavelength and the synthesis of a complex unit cell are effective for achieving high power factor.

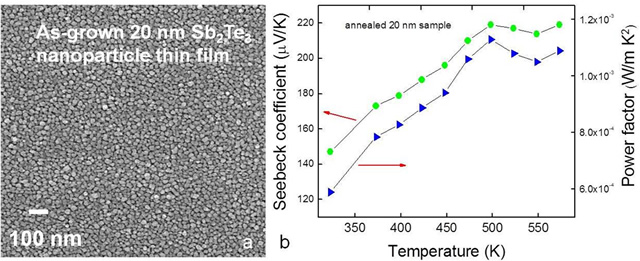

20 nm Sb2Te3 nanoparticles directly synthesized by CVD method showed a higher Seebeck coefficient compared to the larger size nanoparticles (50nm and 100nm).9 Although the conductivity decreased a little, the smaller size particle still demonstrated a higher power factor.

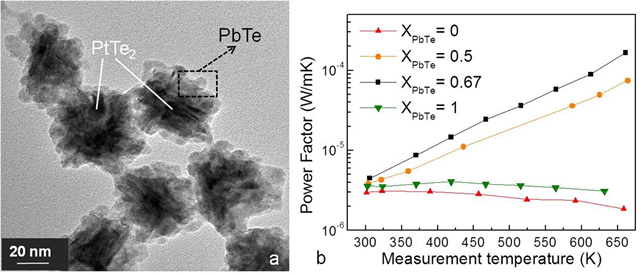

Similarly, uniformly mixed PbTe-PtTe2 multi-phased nanoparticles showed an enhancement in the power factor by more than two orders of magnitude as compared to pure PbTe through tuning the charge carrier concentration by adjusting the PbTe:PtTe2 ratio.10

Figure 2. (a) SEM image of the Sb2Te3 nanoparticle thin film and (b) its electrical properties.

Figure 3. (a) TEM image of PbTe-PtTe2 binary phased nanoparticles with phase ratio XPbTe = 0.5. (b) Enhancement of power factor in PbTe-PtTe2 binary phased nanoparticle samples with various XPbTe values.

Graphene and Carbon Nanotubes as Thermoelectric Materials

Apart from traditional TE materials, few layers graphene (FLG) and carbon nanotubes (CNTs) as novel TE materials have also been investigated.11,12 Both CNTs and FLG were modified by plasma treatment and exhibit enhanced TE properties. The process of plasma treatment induced defects on the FLG and CNTs and caused the following changes:

- band gap opening

- modification of carrier concentration and

- enhancement of phonon scattering

These modifications lead to enhancement in TE properties of the FLG and CNTs. The FLG films were modified by oxygen plasma and CNTs by argon plasma.

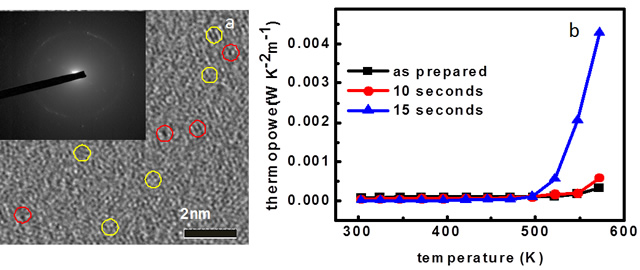

The Seebeck coefficient of FLG was significantly enhanced to ~700 μV/K as compared to ~ 80 μV/K for the pristine FLG films at 575K.11 Meanwhile, the electrical conductivity decrease slightly but still remained at a high value of ~104 S/m. Consequently, the max power factor achieved was ~4.5×10-3 WK-2m-1, which was 15 times higher than that of pristine FLG films.

Figure 4. (a) HRTEM images of FLG films after oxygen plasma treatment. The inset shows the corresponding SAED pattern, which confirms the amorphous status for samples after oxygen plasma treatment. The yellow circles highlight small crystals of caron in such films while the red circles point out the disordered arrangement of carbon atoms. (b) Power factor for the FLG films after different oxygen plasma treatments.

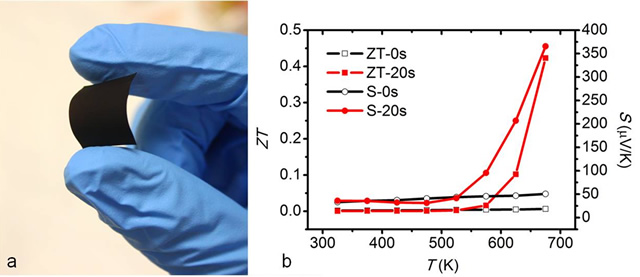

For the CNTs, the samples were prepared as flexible papers. The Seebeck coefficient was increased to ~350 μV/K at 670K, a 7 fold increase as compared to the pristine material at same temperature. Similar to FLG, the electrical conductivity of the plasma treated CNTs also decreased but remained at an acceptable value. The thermal conductivity of CNT papers was very low due to the formation of random networks. In particular, the plasma treated sample showed a very low thermal conductivity of ~0.3 W/(m×K). The ZT value of CNT papers were significantly enhanced to 0.4 from 0.01 after plasma treatment at 670K. Such improvement demonstrate the possibly of using plasma treated CNT papers to fabricate flexible TE devices.12

Figure 5. (a) Optical images of flexsible CNT paper. (b) Enhancement of ZT and Seebeck coefficient of these CNT paper after different Ar plasma treatment durations.

Substitutional Doping with Preferred Orientation Control

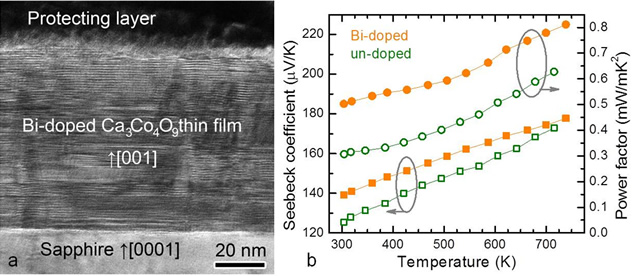

Another approach to enhance power factor is the combination of substitutional doping with preferred orientation control using pulsed laser deposition (PLD) technique. For example, Ca3Co4O9 is one of the best TE oxides due to its high temperature ZT of 0.83 at 1000K.13 However, due to the strong anisotropy in crystal growth and electrical transport, large size single crystals are difficult to fabricate.13 By using PLD, thin films that were well crystallized with perfect c-axis orientation could be prepared, and the in-plane electrical properties were found to be comparable to single crystals.14 Furthermore, Bi substitution could reduce the electrical resistivity of the thin films while enhancing the Seebeck coefficient. The power factor of Bi-doped Ca3Co4O9-based thin films were found to improve ~21% and reached 1.016 mWm-1K-2 at 950 K.15

Figure 6. (a) TEM image of Bi-doped Ca3Co4O9 thin film. (b) Enhancement of Seebeck coefficient and power factor by Bi substitution.

Summary

In summary, nanostructuring can be applied by various advanced techniques and can provide great opportunity to improve the TE performance of both conventional and new materials. Further optimization and scaling will broaden the application of TE devices in the near future so that they may be used to improve energy efficiency and decrease CO2 emissions.